Lets take a peak first on how a lead could manage to destroy an environment and to human being. There is no really visible damage contribution to it but the effect is through its contribution of elements in the air (specifically the melting copper).

The impact categories included in the Lead-Free Solder Project [LFSP] and life-cycle impact assessment [LCIA] are as follows: renewable resource use, nonrenewable materials use, energy use, landfill space use, global warming, stratospheric ozone depletion, photochemical smog, air acidification, air particulates, water eutrophication (nutrient enrichment), water quality (biological oxygen demand [BOD] and total suspended solids [TSS]), occupational human health effects (cancer and non-cancer), public human health effects (cancer and non-cancer), and aquatic ecotoxicity.

Iron Solder

Here is a solder flux paste to a least minimize the toxic content of the lead that may cause damage to environment and human body. This is a solder flux paste that can be used on steel, iron, braze, plated-zinc, and plated-nickel soldering for general purposes. Xihan solder flux paste is a product into it. Xihan, is based in Ningbo, Shanghai, China and exports quality solder flux paste to any part of the world. So how can interested buyers contact Xihan? They provide a site on web to contact them and know more about the product. It can be ordered in hundreds for they can accommodate 3000 pieces-per-day order and they never ran out of stock. Worth .6-0.8/pc, you can have them on time.

Impacts from the transportation and distribution of materials, products, and wastes throughout the life-cycle of a solder are included in most of the upstream processes where secondary data are used that already include transportation. Like Xihan, they also make provide time frame in delivery not long enough to wait but not fast enough to surprise you... they consider seven to ten working days delivery time. Data for manufacturing and use/application life-cycle stages reflect the period stated.

Unlike most products, solder does not have a use life-cycle that extends over a large time frame, instead it occurs over the relatively short period of time required to assemble a printed wiring board. And to whatever business anyone ventures, please also understand any risk that takes part of it. No matter what kind of industrial business we are in. Always remember that anything should also be of good service not just to your client but also to the nature, who deserves much credit to our existence.

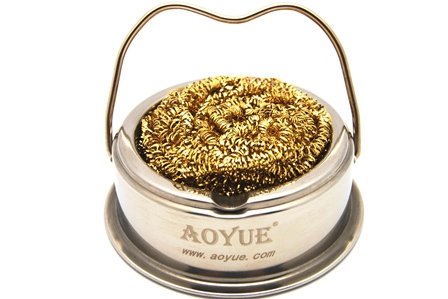

Christmas Sales Aoyue Soldering Iron Tip Cleaner with Brass wire sponge, no water needed 201

Dec 09, 2011 19:40:50

Click for larger image and other views

Christmas Sales Aoyue Soldering Iron Tip Cleaner with Brass wire sponge, no water needed Feature

- Cleans Tip without Messy Wet Sponges

- Uses Low abrasive Brass, no water needed

- Works with any tip

- Heat resistant Stainless Steel Case

- lengthens tip life by reducing oxidation

Christmas Sales Aoyue Soldering Iron Tip Cleaner with Brass wire sponge, no water needed Overview

Cleans your soldering iron tips without water and is faster and better than a sponge! Made from coils of brass, which are softer than the tip plating yet hard enough to lessen oxidationTo clean the tip, simply plunge the iron tip into the coils. This cleans better than a wet sponge and won't reduce the tip temperature.SAVE NOW on Christmas Sales Offers below!

Available In Stock. |

| This Christmas Aoyue Soldering Iron Tip Cleaner with Brass wire sponge, no water needed ships for FREE with Super Saver Shipping. |

Price : Click to Check Update Prices Please. |